Tool Management is shown.

Download Tool Tracking for free.

CNC tool crib software

Tool crib management software

Tool management software

CNC Tool management software

Tool pre-setting

and tool

management result

in the single largest

efficiency gain for

the size of its

investment.

The costs maybe

relatively low but it

requires time and

effort to implement.

Most systems on the

market will

overwhelm you with

tedious data input

and a high learning

curve.

Evaluate our

approach using this

simulator. The User

Interface (UI) work

flow is the same as

in our system.

Tool pre-setting and

tool management

result in the single

largest efficiency gain

for the size of its

investment.

The costs maybe

relatively low but it

requires time and effort to

implement.

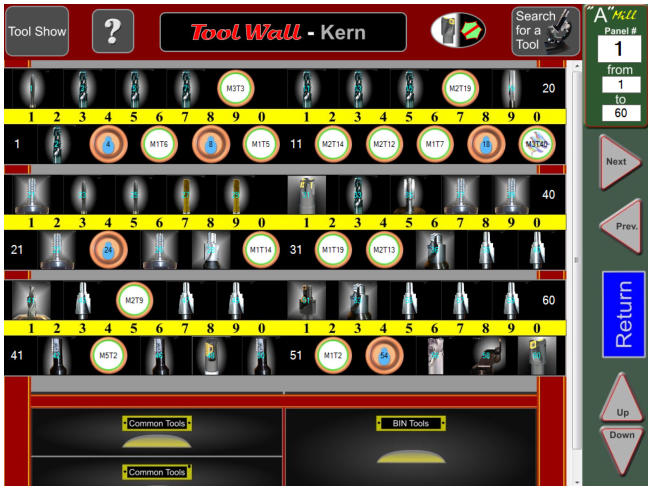

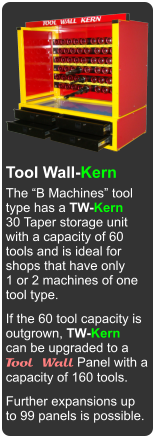

“B-Machine Type”

The “B Machines” tool

type has a Tool Wall

50 Taper storage unit.

A 50 Taper Tool Wall

panel has a 60 tool

capacity and can be

expanded to 99 panels.

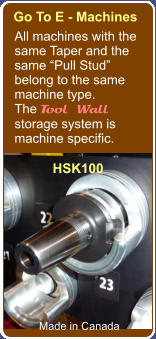

“E-Machine Type”

The “E Machines” tool

type has a Tool Wall

HSK100 storage unit.

A HSK100 Tool Wall

panel has a 60 tool

capacity and can be

expanded to 99 panels.

“D-Machine Type”

The “D Machines” tool

type has a Tool Wall

HSK63 storage unit.

A HSK63 Tool Wall

panel has a 60 tool

capacity and can be

expanded to 99 panels.

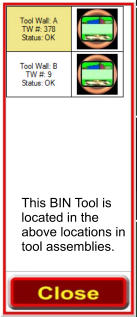

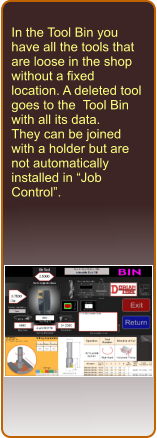

In the Tool Bin you

have all the tools that

are loose in the shop

without a fixed

location. A deleted tool

goes to the Tool Bin

with all its data.

They can be joined

with a holder but are

not automatically

installed in “Job

Control”.

The ? marks a “Help” feature

location, answering questions using

the

Virtual Tool Wall.

This facility is not only used for Tool Wall demonstration, but

doubles as the software’s “Help” module and is accessible

from within the Virtual Tool Wall software.

The Help background contains Links that navigates to certain

videos or sections of this demo and answers specific question

topics.

To implement a tool management system is not an

instant gratification experience as you will have to put

in your tool data first to make it happening. If you

have a lot of tools, that will take time. Note, your

company is never too small for Tool Wall. It is just a

lot easier as you have less data to enter to start.

Once done though, you'll never want to go back as

operations are much less complicated and much

more efficient.

Tool Wall is a system that can be expanded at any

time. We suggest to start small and get the hang of it

first. Expanding gets a lot faster too when you know

the system and it is easier to justify an expansion

when you have seen the results.

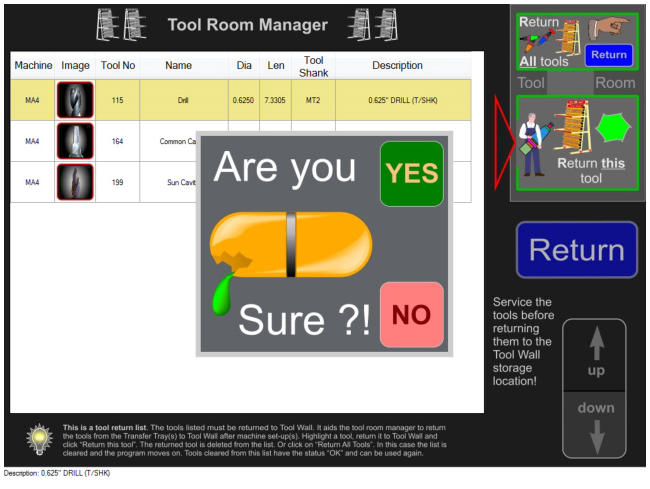

The Tool Room feature allows shops to combine the “Programmer” job function with the Tool Room

operation. In Tool Wall the set-up for a new job is logistically done in the Tool Room. The machine operator has

to follow only the instructions provided by the Programmer in the Tool Room, adding to a more efficient work-flow.

The Tool Room feature allows shops to combine the “Programmer” job function with the Tool Room operation. In

Tool Wall the set-up for a new job is logistically done in the Tool Room. The machine operator has to follow only

the instructions provided by the Programmer in the Tool Room, adding to a more efficient work-flow.

The Tool Room feature allows shops to combine the “Programmer” job function with the Tool Room operation. In

Tool Wall the set-up for a new job is logistically done in the Tool Room. The machine operator has to follow only

the instructions provided by the Programmer in the Tool Room, adding to a more efficient work-flow.

Maintenance

Alert

Basic or machine

specific maintenance

alerts are displayed.

Maintenance is

structured by dates

starting with the date

you entered.

If a machine

manufacturer is

participating their

machine specific

program is resident.

Note: This section is

still under

development.

Frequently asked Questions:

Do Tool Wall Tools have a RF chip to record tool movement: No they have not. (implementation of RFID in testing stage)

How does the software know where a tool is: All tool movement are made through Tool Wall.

What if operators skip entries: All offset data are resident in Tool Wall. Since an operator needs these data to operate the

tool, he/she has to send the data from Tool Wall to the machine. Hence the program knows the tool location and entries

stay current.

My company is too small for tool management: This is the best time to implement a tool management as tools have to be

entered into the system first. It is much easier to enter the data for 60 tools than for 600 or more.

How does my small company benefit from tool/job management: Regardless of being a small or large company, setting up

for a new job takes time. Tool Wall reduces that to only a fraction and all operators can do it.

Do I need a pre-setter for Tool Wall tool management: Yes. In Tool Wall all tool are preset for instant deployment. The

preset values are stored with each tool in the tool management system.

I am measuring tools with a gauge block. It woks fine for me: Think again! The machine is not running during that process.

With a pre-setter you can set the tools while the machine is running. Most operations need only an in-expensive contact

pre-setter. Pay-back will be in a few month.

Is Tool Wall suitable for a Tool Room operation: Yes. Enable the Tool Room option. The tool room manager has control over

all tools, inventory, tool deployment for all jobs.

Where is the Pay-Back using Tool Wall with a tool room operation: Depending on the size of the operation, combine the job

of the Tool Room Manager with the job of your programmer. He has now the full control over all the jobs and associated tool

deployment. It is now a lot easier for the programmer to select the right tool for his code and can use the Tool Wall data for

programming. Give your Programmer/Tool Room Manager a helper if needed.

Do I have to have a Tool Wall storage: No, the software has a setting that is in the List Format, suitable for any tool storage

you may already have.

5S brings vast Productivity, Organisational, Neatness,

Standardisation and Safety improvements when implemented.

5S(methodology) tool handling system

Tool Tracking and Tool Management have the same UI (user interface)

In order to start you out faster and to reduce the tedious data input in the beginning, the Consumable

Module is disabled in Tool Tracking. Download Tool Tracking and evaluate if Tool Wall works for you.

Activate - More Types

Made in Canada

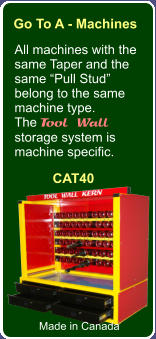

All machines with the

same Taper and the

same “Pull Stud”

belong to the same

machine type.

The Tool Wall

storage system is

physically different

between types. This

insures that tools can

not be mixed up.

A 40 taper tool holder

from a Dawoo

machine can

physically not be

placed into a Tool

Wall belonging to 40

taper Haas machines.