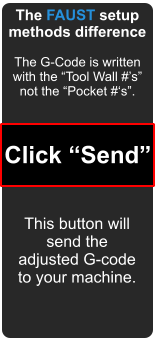

A wizard to convert a

copy of your existing

code is part of this

software.

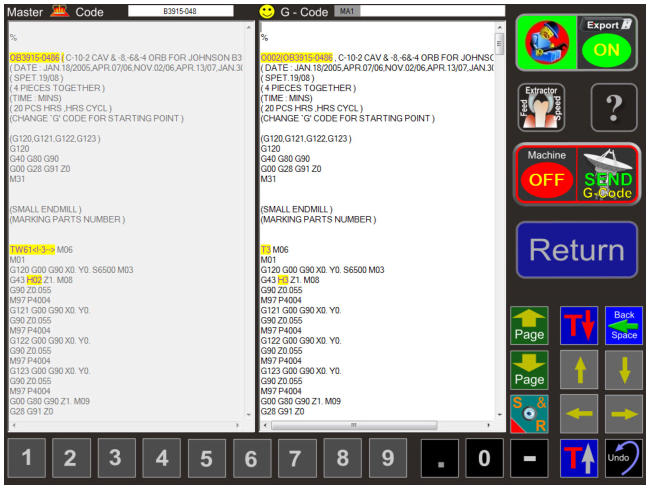

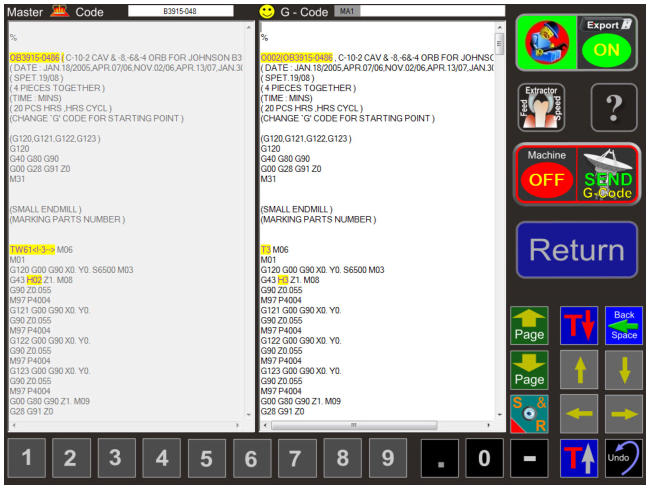

After the Set-Up is

completed and the

Off-Sets have been

sent, a copy of the

“Master Code” is re-

written to the active

G-Code. The Tool

Wall numbers have

now the correct

pocket numbers for

the work to begin.

The S.A.M. job set-up method rewrites the code to adjust to tools that are

already in the tool changer regardless of their position. This reduces the set-

up time making it the ideal set-up method for cells with small production runs.

As demonstrated,

this process is fast

and uncomplicated.

The ability to choose

between the “Twig“,

the “Traditional” and

the “SAM” set-up

method provides

complete flexibility.

The Set-Up with

Tool Wall is not only

efficient but can be

done by less

proficient personnel.

Use the Extractor to

extract and insert Feed

and Speed data.

You can either “Extract

Tool Data from Code”

and store this data with

the tool at the respective

material or “Enter Tool

Data to Code”.

With this feature you

can use one G-Code file

for all materials. For

example: If your code

has the Steel feed and

speed data and you

want to make this part

from Aluminum, use the

Aluminum tool data and

insert the feeds and

speeds into the G-Code.

Extract

“Feed

&

Speed

data

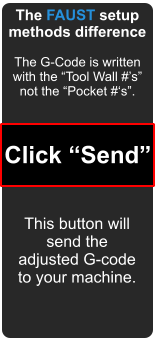

At this point the G-Code

can be edited.

This window gives you

several options:

1) Display the full

keyboard.

2) Search for a string.

3) Search for a string or

value and replace it with

the value entered.

Note: If a file was edited

a file marker is

displayed. All edited files

can now be reviewed at

a later date.

Edit the

G-Code

data

The program adds the <!-3--> to the Tool Wall tool

TW61.

It is done when you position a tool into a specific

pocket using Traditional setup.

TW61<!-3--> tells the program that this tool has to

be placed into pocket #3 when the Traditional

setup is used.